Call Us (855) 374-7216

Cleaning Head Carriage Rail on Your JV33 & JV5 Mimaki Printers

By inkjetparts.net, 4/11/2016

- A regular maintenance procedure on print head carriage rail will ensure proper head carriage travels and longevity of the Y axis motor.

- Many people overlook the dust, dirt and grease accumulated on the carriage rail over time, which causes the bearing assembly and Y motor wear out prematurely.

- A Maintenance procedure should be carried out once a month for printers that run 40 hours or more a week.

- Tools needed are Alcohol, IJP head carriage rail grease, IJP double tip sponge swabs, IJP lint free 100% polyester wipes.

- Turn off the printer and make sure the head carriage is back on the capping station.

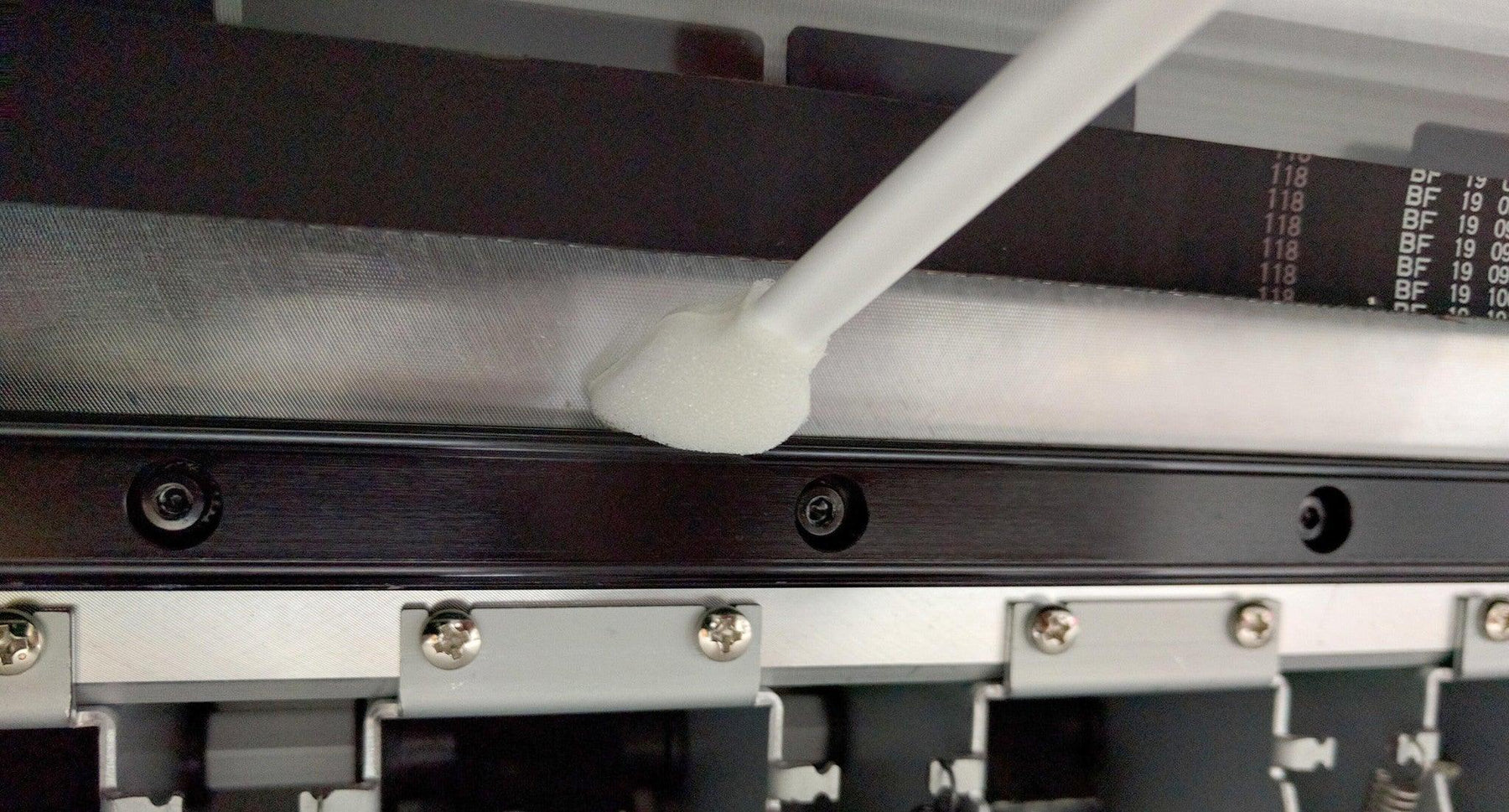

- Above Shows the Mimaki JV5 Y-rail on which the head carriage travels. Clean the front, top and bottom of the rail using a lint free polyester wipe, dampened with Alcohol. DO NOT apply Alcohol directly onto the rail. Doing so may cause premature failure of the bearing.

- Apply IJP grease to the Y-Rail using sponge swab. Ensure the grease is spread out evenly and thin. DO NOT use your fingers to lubricate the Y-Rail with grease.

- Remove any excess grease with a clean lint free polyester wipe. Excess grease can be splattered by the carriage bearings onto the Encoder Strip that controls carriage position and will cause CR errors.

Leave a comment