The Importance of Choosing OEM over Generic Parts

Digital printing is a competitive market and saving money on repairs is more important than ever. Whether you repair printers for a living or you’re trying to cut costs and repair your own, you should consider using OEM parts. Don’t let the higher cost chase you away. Below are a few reasons why OEM parts are often a better option than generic parts.

Durability

Although generic parts may be cheaper initially, they have a much shorter life than OEM parts. OEM stands for Original Equipment Manufacturer, which means they come directly from the manufacturer that makes the product. The manufacturer tests each product to reduce failure. For example, generic printheads last three to six months while OEM printheads can last well over a year.

Quality

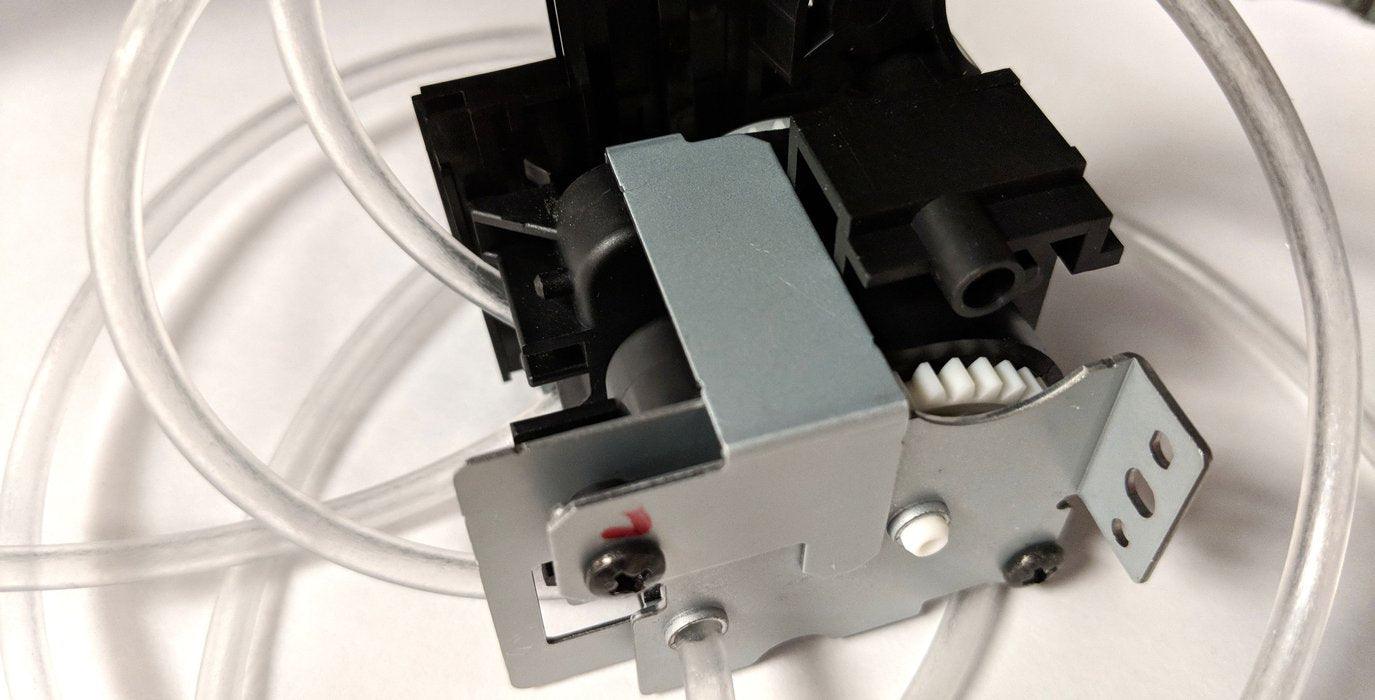

Since OEM parts undergo strict quality testing, they tend to work much better than generic parts. A prime example of this is the damper. Generic dampers have a habit of leaking during use, which affects the print quality. The last thing you need is to get behind on a project because of a faulty damper.

Cost

For many customers, it all comes down to price. As mentioned before, OEM parts last much longer than generic printer parts. This means you won’t be spending money every few months to replace the parts. Take the pump, for example. Generic pumps have very low suction and cause the consumer to use more ink than necessary. The price of ink adds up, often costing more than the pump itself.

If you work on Mimaki, Mutoh or Roland printers or need to repair your own, invest in OEM parts. You deserve a quality part that’s going to last.

Leave a comment