DTF vs DTG vs Screen Printing: Which Printing Method is Right for You?

DTF vs. DTG vs. Screen Printing: Which Printing Method is Right for You?

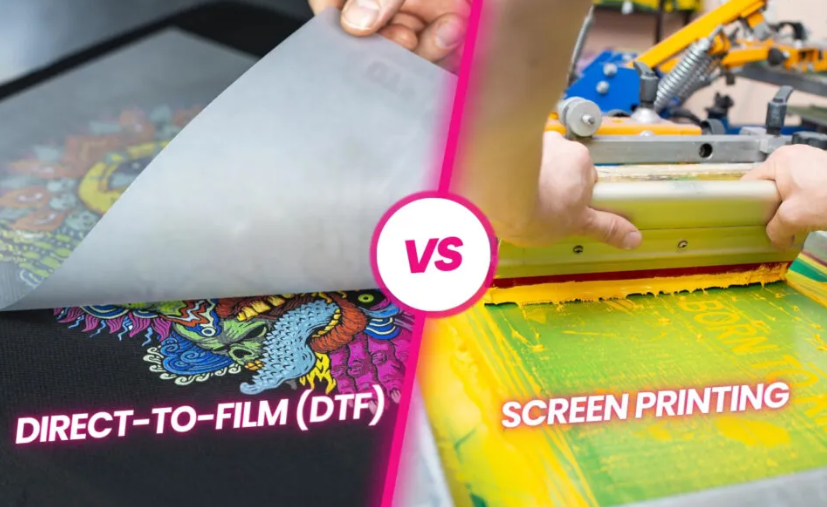

Choosing the right printing method for your custom apparel business or hobby can feel overwhelming. With so many options out there, how do you know which one suits your needs? In this guide, we’ll break down three popular methods—Direct-to-Film (DTF), Direct-to-Garment (DTG), and screen printing—to help you decide. Whether you’re printing vibrant T-shirts, hoodies, or tote bags, understanding the differences in process, cost, quality, and versatility is key. Plus, we’ll highlight why DTF is gaining popularity and how the right equipment can make all the difference.

What is DTF Printing?

Direct-to-Film (DTF) printing is a newer technology that’s taken the apparel industry by storm. Here’s how it works:

- Design and Print: Create your design and print it onto a special PET film using a DTF printer with vibrant, water-based inks.

- Apply Adhesive: Sprinkle adhesive powder onto the wet ink, which sticks to the design.

- Cure and Transfer: Cure the film with heat, then use a heat press to transfer the design onto your fabric.

Key Benefits:

- Works on almost any material: cotton, polyester, blends, leather, and even non-textiles like mugs.

- No pre-treatment required, unlike DTG.

- Vibrant, durable prints that withstand 50+ washes.

- Ideal for small batches or one-off designs.

Drawbacks:

- Requires specialized equipment like DTF printers, films, and powders.

- Initial setup costs can be moderate but are offset by versatility.

Pro Tip: High-quality DTF inks and films ensure crisp, long-lasting prints. Explore our range of DTF supplies to get started.

What is DTG Printing?

Direct-to-Garment (DTG) printing uses inkjet technology to print designs directly onto fabric, much like a regular paper printer.

- Pre-Treatment: Fabrics (usually cotton or cotton blends) are pre-treated with a solution to help ink adhere.

- Print: The design is printed directly onto the garment using a DTG printer.

- Cure: The ink is cured with a heat press or conveyor dryer.

Key Benefits:

- Excellent for detailed, multi-color designs with gradients.

- No setup costs for small runs, making it great for print-on-demand.

- Soft, breathable prints that blend into the fabric.

Drawbacks:

- Limited to cotton or high-cotton blends for best results.

- Pre-treatment adds time and cost.

- Prints may fade faster than DTF or screen printing (20-40 washes).

Pro Tip: DTG shines for small, detailed orders, but material limitations can restrict versatility compared to DTF.

What is Screen Printing?

Screen printing is the traditional gold standard for apparel decoration, used for decades to create bold, durable designs.

- Setup: Create a stencil (screen) for each color in the design.

- Print: Push ink through the screen onto the fabric, one color at a time.

- Cure: Heat-cure the ink to set the design.

Key Benefits:

- Extremely durable prints, lasting 50+ washes.

- Cost-effective for large runs (50+ pieces) due to low per-unit costs.

- Vibrant colors, especially on dark fabrics with underbase layers.

Drawbacks:

- High setup costs for screens, making small runs or one-offs expensive.

- Limited to simpler designs with fewer colors (each color needs a separate screen).

- Time-consuming setup process.

Pro Tip: Screen printing is best for bulk orders, but DTF offers similar durability with more flexibility for small runs.

Key Differences at a Glance

| Feature | DTF | DTG | Screen Printing |

|---|---|---|---|

| Best For | Small to medium runs, diverse materials | Small runs, detailed designs | Large runs, simple designs |

| Material Versatility | Cotton, polyester, blends, non-textiles | Cotton or high-cotton blends | Most fabrics, best on cotton |

| Setup Time/Cost | Moderate (no screens needed) | Low (pre-treatment required) | High (screens per color) |

| Print Durability | High (50+ washes) | Moderate (20-40 washes) | High (50+ washes) |

| Design Complexity | High (full-color, gradients) | High (full-color, gradients) | Moderate (limited by colors) |

| Cost for Small Runs | Cost-effective | Cost-effective | Expensive |

Which Method Should You Choose?

- Choose DTF if you want versatility across fabrics, vibrant prints, and the ability to handle small to medium runs without breaking the bank. It’s perfect for businesses looking to offer custom apparel, accessories, or even hard goods like mugs. Check out our DTF printers and supplies to start printing today.

- Choose DTG if you’re focused on cotton-based apparel with intricate, colorful designs and prefer a print-on-demand model. Be prepared for pre-treatment and maintenance costs.

- Choose Screen Printing if you’re producing large quantities of simple designs and need unbeatable durability. It’s less practical for small, custom orders.

Why DTF is Gaining Popularity

DTF printing strikes a balance between the flexibility of DTG and the durability of screen printing. Its ability to print on virtually any surface without pre-treatment makes it a game-changer for small businesses and hobbyists. Plus, with the right equipment—like reliable DTF printers, high-quality inks, and durable PET films—you can achieve professional results at a fraction of the cost of traditional methods.

Get Started with DTF Printing Today

Ready to jump into DTF printing? It’s easier than you think with the right tools. From DTF printers to adhesive powders and heat presses, we’ve got everything you need to create stunning, durable prints. Browse our DTF parts and supplies to find high-quality equipment tailored to your needs. Want to learn more? Download our free “DTF Printing Starter Guide” for tips on setup, maintenance, and avoiding common mistakes.

Happy printing!

Leave a comment